Processing Routes of Steelmaking

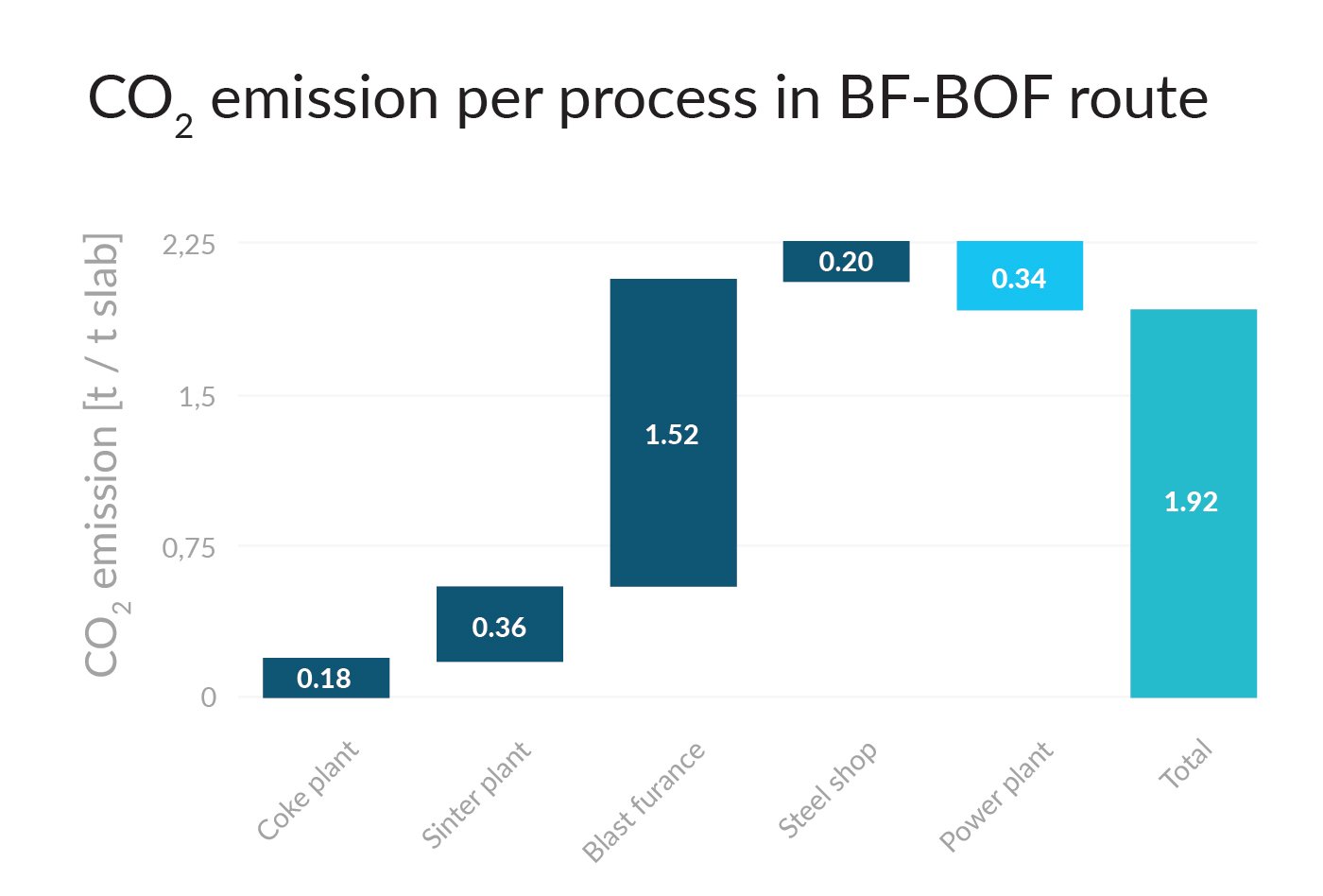

There are two main processing routes used to make steel tonnage today. The Electric Arc Furnace (EAF) route commonly uses various combinations of scrap, Direct Reduced Iron (DRI) and pig iron, generates 0.3-0.7 tonne CO2/tonne steel, and is considered the route to the lowest CO2 emissions available today. The integrated steelmaking or Blast Furnace to Basic Oxygen Furnace (BF-BOF) route typically generates near or sometimes above 2.0 tonne CO2/tonne steel and makes up the majority of steel processed worldwide today at 71%.